E3Z

Capteurs d'utilisation générale dans un boîtier compact en plastique

Format compact et LED haute puissance pour un excellent rapport performance-taille et le meilleur rapport valeur-performance pour les applications standard.

- Déviation optique minimale pour un alignement facile

- IP67 et IP69k pour une résistance extrême à l'eau

- Blindage renforcé pour la meilleure protection antiparasite (EMC)

- Boîtier multiple PBT robuste pour une grande résistance mécanique

Caractéristiques et références

| Produit | Shape | Sensing method | Sensing distance | Sensing distance (min.) | Setting method | Connection method | Cable length | Output type | Operation mode | Response time | Material housing | Thread size | Type of light | Spot size | Power supply voltage | Features | Degree of protection (IP) | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

Cuboid | Diffuse reflective | 100 mm | 5 mm | Manual adjustment | Cable | 0.5 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | CELL PHOTO DIR 10CM CC NPN CAB0.5M |

|

|

|

|

Cuboid | Diffuse reflective | 100 mm | 5 mm | Manual adjustment | Cable | 2 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | Cellule photoélectrique à réflexion directe, 10 cm CC NPN, câble 2 m |

|

|

|

|

Cuboid | Diffuse reflective | 100 mm | 5 mm | Manual adjustment | Cable | 5 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | CELL PHOTO DIR 10CM CC NPN CAB5M |

|

|

|

|

Cuboid | Diffuse reflective | 100 mm | 5 mm | Manual adjustment | M12 pigtail connector | 0.3 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | CELLULE PHOTO DIR |

|

|

|

|

Cuboid | Diffuse reflective | 1000 mm | Manual adjustment | Cable | 0.5 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | CELL PHOTO DIR 1M CC NPN CAB0.5M |

|

||

|

|

Cuboid | Diffuse reflective | 1000 mm | Manual adjustment | Cable | 2 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | IP67 | Cellule photoélectrique à réflexion directe, 1 m, CC NPN, câble 2 m |

|

|||

|

|

Cuboid | Diffuse reflective | 1000 mm | Manual adjustment | Cable | 5 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | Capteur photoélectrique, diffus, 1 m, c.c., 3 fils, NPN, câble de 5 m (nécessite 1 support) |

|

||

|

|

Cuboid | Diffuse reflective | 1000 mm | Manual adjustment | M12 pigtail connector | 0.3 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | CELL PHOTO DIR HUIL 1M NPN CONM12 |

|

||

|

|

Cuboid | Diffuse reflective | 1000 mm | Manual adjustment | M12 pigtail connector | 0.3 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Protective tube cable | IP67 | CELLULE PHOTO DIR |

|

||

|

|

Cuboid | Diffuse reflective | 1000 mm | M8 pigtail connector 4 pin | 0.3 m | NPN | Dark-ON, Light-ON | Plastic | Infrared light | IP67 | Cellule photoélectrique, boîtier rectangulaire, LED infrarouge, diffuse, 1 m, NPN, Light-ON/Dark-ON, connecteur torsadé M8 à 4 broches, 0,3 m |

|

|||||||

|

|

Cuboid | Diffuse reflective | 100 mm | 5 mm | Manual adjustment | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | Cellule photoélectrique à réflexion directe, 10 cm, CC PNP, connecteur M08 |

|

||

|

|

Cuboid | Diffuse reflective | 1000 mm | Manual adjustment | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | Cellule photoélectrique à réflexion directe, 1 m, CC NPN, connecteur M08 |

|

|||

|

|

Cuboid | Diffuse reflective | 100 mm | 5 mm | Manual adjustment | Cable | 0.5 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | CELL PHOTO DIR 10CM CC PNP |

|

|

|

|

Cuboid | Diffuse reflective | 100 mm | 5 mm | Manual adjustment | Cable | 2 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | Réflexion directe, 10 cm, faisceau large, PNP, IP67, câble 2 m |

|

|

|

|

Cuboid | Diffuse reflective | 100 mm | 5 mm | Manual adjustment | Cable | 5 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | Réflexion directe, 10 cm, faisceau large, PNP, IP67, câble 5 m |

|

|

|

|

Cuboid | Diffuse reflective | 100 mm | 5 mm | Manual adjustment | M12 pigtail connector | 0.3 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | CELL PHOTO DIR 10CM CC PNP CONM12 |

|

|

|

|

Cuboid | Diffuse reflective | 100 mm | 5 mm | Manual adjustment | M8 pigtail connector 4 pin | 0.3 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | CELL PHOTO DIR 10CM CC PNP CONM08 |

|

|

|

|

Cuboid | Diffuse reflective | 1000 mm | Manual adjustment | Cable | 0.5 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | CELL PHOTO DIR 1M CC PNP 0.5M |

|

||

|

|

Cuboid | Diffuse reflective | 1000 mm | Manual adjustment | Cable | 2 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | Réflexion directe, 100 cm, PNP, IP67, câble 2 m |

|

||

|

|

Cuboid | Diffuse reflective | 1000 mm | Manual adjustment | Cable | 5 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | CELL PHOTO DIR 1M CC PNP 5M |

|

||

|

|

Cuboid | Diffuse reflective | 1000 mm | IO-Link, Manual adjustment | Cable | 2 m | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 10-30 V | IP67 | Cellule photoélectrique, réflexion diffuse, 1m, DC, PNP, câble 2m, IO-link, COM 3 |

|

|||

|

|

Cuboid | Diffuse reflective | 1000 mm | IO-Link, Manual adjustment | Cable | 5 m | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 10-30 V | IP67 | Cellule photoélectrique, réflexion diffuse, 1m, DC, PNP, câble 5m, IO-link, COM 3 |

|

|||

|

|

Cuboid | Diffuse reflective | 1000 mm | Manual adjustment | M12 pigtail connector | 0.3 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | CELL PHOTO DIR 1M CC PNP CONM12 |

|

||

|

|

Cuboid | Diffuse reflective | 1000 mm | Manual adjustment | M12 pigtail connector | 0.3 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Protective tube cable | IP67 | CELL PHOTO DIR 1M CC PNP CONM12 |

|

||

|

|

Cuboid | Diffuse reflective | 1000 mm | IO-Link, Manual adjustment | M12 pigtail Smartclick connector | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 10-30 V | IP67 | Cellule photoélectrique, réflexion diffuse, 1m, DC, PNP, précâblée connecteur M12, IO-Link, COM3 |

|

|||

|

|

Cuboid | Diffuse reflective | 1000 mm | Manual adjustment | M8 pigtail connector 4 pin | 0.3 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | CELL PHOTO DIR 1M CC PNP CONM08 |

|

||

|

|

Cuboid | Diffuse reflective | 1000 mm | Manual adjustment | M8 pigtail connector 3 pin | 0.3 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | IP67 | Capteur photoélectrique, diffus, 1 m, c.c., 3 fils, L-ON/D-ON sélectionnable, sortie PNP, connecteur M8 en tire-bouchon 3 broches |

|

|||

|

|

Cuboid | Diffuse reflective | 100 mm | 5 mm | Manual adjustment | Connector M8 - 4 pin | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | Cellule photoélectrique à réflexion directe, 10 cm, faisceau large, PNP, IP67, connecteur M8 4 broches |

|

||

|

|

Cuboid | Diffuse reflective | 1000 mm | Manual adjustment | Connector M8 - 4 pin | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | Wide beam | IP67 | Cellule photoélectrique à réflexion directe, 100 cm, PNP, IP67, connecteur M8 4 broches |

|

|||

|

|

Cuboid | Diffuse reflective | 1000 mm | IO-Link, Manual adjustment | Connector M8 - 4 pin | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 10-30 V | Wide beam | IP67 | Cellule photoélectrique, réflexion diffuse, 1m, DC, PNP, connecteur M8, IO-link, COM 3 |

|

|||

|

|

Cuboid | Diffuse reflective | 90 mm | 60 mm | Manual adjustment | Cable | 0.5 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 2.5 mm | 12-24 V | Narrow beam | IP67 | CELL PHOTO DIR 9CM NPN CC CAB0.5M |

|

|

|

Cuboid | Diffuse reflective | 90 mm | 60 mm | Manual adjustment | Cable | 2 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 2.5 mm | 12-24 V | Narrow beam | IP67 | CELL PHOTO DIR 9CM NPN CC CAB2M |

|

|

|

Cuboid | Diffuse reflective | 90 mm | 60 mm | Manual adjustment | Cable | 5 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 2.5 mm | 12-24 V | Narrow beam | IP67 | CELL PHOTO DIR 9CM NPN CC CAB5M |

|

|

|

Cuboid | Diffuse reflective | 90 mm | 60 mm | Manual adjustment | M12 pigtail connector | 0.3 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 2.5 mm | 12-24 V | Narrow beam | IP67 | CELL PHOTO DIR 9CM NPN CC CONM12 |

|

|

|

Cuboid | Limited reflective | 30 mm | Manual adjustment | Cable | 2 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 2 mm | 12-24 V | Narrow beam | IP67 | CELL PHOTO DIRECT FAISCEAU FIN |

|

|

|

|

Cuboid | Diffuse reflective | 90 mm | 60 mm | Manual adjustment | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 2.5 mm | 12-24 V | Narrow beam | IP67 | CELL PHOTO DIR 9CM NPN CC CONM08 |

|

|

|

|

Cuboid | Limited reflective | 30 mm | Manual adjustment | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 2 mm | 12-24 V | Narrow beam | IP67 | CELL PHOTO DIRECT FAISCEAU FIN |

|

||

|

|

Cuboid | Diffuse reflective | 90 mm | 60 mm | Manual adjustment | Cable | 0.5 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 2.5 mm | 12-24 V | Narrow beam | IP67 | Réflexion directe, 90±30 mm avec spot étroit de 2,5 mm, PNP, IP67, câble 0.5 m |

|

|

|

Cuboid | Diffuse reflective | 90 mm | 60 mm | Manual adjustment | Cable | 2 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 2.5 mm | 12-24 V | Narrow beam | IP67 | Réflexion directe, 90±30 mm avec spot étroit de 2,5 mm, PNP, IP67, câble 2 m |

|

|

|

Cuboid | Diffuse reflective | 90 mm | 60 mm | Manual adjustment | Cable | 5 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 2.5 mm | 12-24 V | Narrow beam | IP67 | CELL PHOTO DIR 9CM PNP CC CAB5M |

|

|

|

Cuboid | Diffuse reflective | 90 mm | 60 mm | IO-Link, Manual adjustment | Cable | 2 m | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 2.5 mm | 10-30 V | Narrow beam | IP67 | Cellule photoélectrique, réflexion diffuse, 90mm, faisceau étroit, DC, PNP, câble 2m, IO-link, COM 3 |

|

|

|

Cuboid | Diffuse reflective | 90 mm | 60 mm | IO-Link, Manual adjustment | Cable | 5 m | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 2.5 mm | 10-30 V | Narrow beam | IP67 | Cellule photoélectrique, réflexion diffuse, 90mm, faisceau étroit, DC, PNP, câble 5m, IO-link, COM 3 |

|

|

|

Cuboid | Diffuse reflective | 90 mm | 60 mm | Manual adjustment | M12 pigtail connector | 0.3 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 2.5 mm | 12-24 V | Narrow beam | IP67 | CELL PHOTO DIR 9CM PNP CC CONM12 |

|

|

|

Cuboid | Limited reflective | 30 mm | Manual adjustment | Cable | 2 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 2 mm | 12-24 V | Narrow beam | IP67 | Réflexion directe, 30±20 mm avec spot étroit de 2,5 mm, PNP, IP67, câble 2 m |

|

|

|

|

Cuboid | Diffuse reflective | 90 mm | 60 mm | Manual adjustment | Connector M8 - 4 pin | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 2.5 mm | 12-24 V | Narrow beam | IP67 | Réflexion directe, 90±30 mm avec spot étroit de 2,5 mm, PNP, IP67, connecteur M8 4 broches |

|

|

|

|

Cuboid | Diffuse reflective | 90 mm | 60 mm | IO-Link, Manual adjustment | Connector M8 - 4 pin | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 2.5 mm | 10-30 V | Narrow beam | IP67 | Cellule photoélectrique, réflexion diffuse, 90mm, faisceau étroit, DC, PNP, connecteur M8, IO-link, COM 3 |

|

|

|

|

Cuboid | Limited reflective | 30 mm | 60 mm | Manual adjustment | Connector M8 - 4 pin | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 2 mm | 12-24 V | Narrow beam | IP67 | Réflexion directe, 30±20 mm avec spot étroit de 2,5 mm, PNP, IP67, connecteur M8 4 broches |

|

|

|

|

Cuboid | Background suppression | 200 mm | 20 mm | Manual adjustment | Cable | 0.5 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 12-24 V | IP67 | CELL PHOTO SUP A/P 20CM NPN CAB0.5M |

|

||

|

|

Cuboid | Background suppression | 200 mm | 20 mm | Manual adjustment | Cable | 2 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 12-24 V | IP67 | CELL PHOTO SUP A/P 20CM NPN CAB2M |

|

||

|

|

Cuboid | Background suppression | 200 mm | 20 mm | Manual adjustment | M12 pigtail connector | 0.3 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 12-24 V | IP67 | CELL PHOTO SUP A/P 20CM NPN CONM12 |

|

||

|

|

Cuboid | Background suppression | 80 mm | 2 mm | Manual adjustment | Cable | 0.5 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 12-24 V | IP67 | CELL PHOTO SUP A/P 08CM NPN CAB0.5M |

|

||

|

|

Cuboid | Background suppression | 80 mm | 2 mm | Manual adjustment | Cable | 2 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 12-24 V | IP67 | CELL PHOTO SUP A/P 08CM NPN CAB2M |

|

||

|

|

Cuboid | Background suppression | 200 mm | 20 mm | Manual adjustment | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 12-24 V | IP67 | CELL PHOTO SUP A/P 20CM NPN CONM08 |

|

|||

|

|

Cuboid | Background suppression | 80 mm | 2 mm | Manual adjustment | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 12-24 V | IP67 | CELL PHOTO SUP A/P 08CM NPN CONM08 |

|

|||

|

|

Cuboid | Background suppression | 200 mm | 20 mm | Manual adjustment | Cable | 0.5 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 12-24 V | IP67 | CELL PHOTO SUP A/P 20CM PNP CAB0.5M |

|

||

|

|

Cuboid | Background suppression | 200 mm | 20 mm | Manual adjustment | Cable | 2 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 12-24 V | IP67 | Réflexion directe avec suppression d'avant ou d'arrière plan, 20 cm, PNP, IP67, câble 2 m |

|

||

|

|

Cuboid | Background suppression | 200 mm | 20 mm | Manual adjustment | Cable | 5 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 12-24 V | IP67 | Réflexion directe avec suppression d'avant ou d'arrière plan, 20 cm, PNP, IP67, câble 5 m |

|

||

|

|

Cuboid | Background suppression | 200 mm | 20 mm | Manual adjustment | M12 pigtail connector | 0.3 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 12-24 V | IP67 | CELL PHOTO SUP A/P 20CM PNP CONM08 |

|

||

|

|

Cuboid | Background suppression | 200 mm | 20 mm | Manual adjustment | M8 pigtail connector 4 pin | 0.3 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 12-24 V | IP67 | CELL PHOTO SUP A/P 20CM PNP CONM08 |

|

||

|

|

Cuboid | Background suppression | 80 mm | 2 mm | Manual adjustment | Cable | 0.5 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 12-24 V | IP67 | CELL PHOTO SUP A/P 08CM PNP CAB0.5M |

|

||

|

|

Cuboid | Background suppression | 80 mm | 2 mm | Manual adjustment | Cable | 2 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 12-24 V | IP67 | Réflexion directe avec suppression d'avant ou d'arrière plan, Sn=80 mm, spot 2 mm, PNP, IP67, câble 2 m |

|

||

|

|

Cuboid | Background suppression | 200 mm | 20 mm | Manual adjustment | Connector M8 - 4 pin | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 12-24 V | IP67 | Réflexion directe avec suppression d'avant ou d'arrière plan, 20 cm, PNP, IP67, connecteur M8 |

|

|||

|

|

Cuboid | Background suppression | 80 mm | 2 mm | Manual adjustment | Connector M8 - 4 pin | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarity free red light | 12-24 V | IP67 | Réflexion directe avec suppression d'avant ou d'arrière plan, Sn=80 mm, spot 2 mm, PNP, IP67, connecteur M8 |

|

|||

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | Manual adjustment | Cable | 0.5 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | M.S.R. | IP67 | Capteur photoélectrique, rétro-réfléchissant, 4 m, c.c., 3 fils, NPN (1 support et 1 réflecteur requis) |

|

|

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | Manual adjustment | Cable | 2 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | M.S.R. | IP67 | Cellule photoélectrique à réflecteur, 4 m, CC NPN, câble 2 m |

|

|

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | Manual adjustment | Cable | 5 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | M.S.R. | IP67 | CELL PHOTO REFL4M CC NPN CAB5M |

|

|

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | Manual adjustment | M12 pigtail connector | 0.3 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | M.S.R. | IP67 | CELL PHOTO HUIL REFL4M NPN CONM12 |

|

|

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | Manual adjustment | M8 pigtail connector 4 pin | 0.3 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | M.S.R. | IP67 | CELL PHOTO REFLEX NPN |

|

|

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | Manual adjustment | M8 pigtail connector 3 pin | 0.3 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | M.S.R. | IP67 | CELL PHOTO HUIL REFL4M NPN CONM08 |

|

|

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | Manual adjustment | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | M.S.R. | IP67 | Cellule photoélectrique à réflecteur, 4 m, CC NPN, connecteur M08 |

|

||

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | Manual adjustment | Cable | 0.5 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | M.S.R. | IP67 | Capteur photoélectrique, rétro-réfléchissant, 4 m, c.c., 3 fils, PNP (nécessite 1 support et 1 réflecteur) |

|

|

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | Manual adjustment | Cable | 2 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | M.S.R. | IP67 | A réflecteur, 4 m, filtre de polarisation, PNP, IP67, câble 2 m |

|

|

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | Manual adjustment | Cable | 5 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | M.S.R. | IP67 | CELL PHOTO REFL4M CC PNP CAB5M |

|

|

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | IO-Link, Manual adjustment | Cable | 2 m | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 10-30 V | M.S.R. | IP67 | Cellule photoélectrique, sur réflecteur, 4m, DC, PNP, câble 2m, IO-link, COM 3 |

|

|

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | IO-Link, Manual adjustment | Cable | 5 m | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 10-30 V | M.S.R. | IP67 | Cellule photoélectrique, sur réflecteur, 4m, DC, PNP, câble 5m, IO-link, COM 3 |

|

|

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | Manual adjustment | M12 pigtail connector | 0.3 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | M.S.R. | IP67 | CELL PHOTO REFL4M CC PNP CONM12 |

|

|

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | Manual adjustment | M12 pigtail Smartclick connector | 0.3 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | M.S.R. | IP67 | CELL PHOTO REFL |

|

|

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | IO-Link, Manual adjustment | M12 pigtail Smartclick connector | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 10-30 V | M.S.R. | IP67 | Cellule photoélectrique, sur réflecteur, 4m, DC, PNP, précâblée connecteur M12, IO-link, COM 3 |

|

|

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | Manual adjustment | M8 pigtail connector 4 pin | 0.3 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | M.S.R. | IP67 | CELL PHOTO REFL4M CC PNP CONM08 |

|

|

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | Manual adjustment | M8 pigtail connector 3 pin | 0.3 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | M.S.R. | IP67 | CELL PHOTO REFL4M CC PNP CONM08 |

|

|

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | Manual adjustment | Connector M8 - 4 pin | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | M.S.R. | IP67 | Cellule photoélectrique à réflecteur, 4 m, filtre de polarisation, PNP, IP67, connecteur M8 4 broche |

|

||

|

|

Cuboid | Retro-reflective | 4000 mm | 100 mm | IO-Link, Manual adjustment | Connector M8 - 4 pin | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 10-30 V | M.S.R. | IP67 | Cellule photoélectrique, sur réflecteur, 4m, DC, PNP, connecteur M8, IO-link, COM 3 |

|

||

|

|

Cuboid | Through-beam | 15000 mm | Manual adjustment | Cable | 0.5 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | IP67 | Barrage, 15 m, DEL infrarouge, NPN, IP67, câble 0,5 m |

|

|||

|

|

Cuboid | Through-beam | 15000 mm | Manual adjustment | Cable | 2 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | IP67 | Cellule photoélectrique barrage 15m CC NPN câble 2m |

|

|||

|

|

Cuboid | Through-beam | 15000 mm | Manual adjustment | Cable | 5 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | IP67 | Capteur photoélectrique, barrage, 15 m, c.c., 3 fils, NPN, câble de 5 m (nécessite 2 supports) |

|

|||

|

|

Cuboid | Through-beam | 15000 mm | Manual adjustment | M12 pigtail connector | 0.3 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | IP67 | CELL PHOTO BARR15M CC NPN CONM12 |

|

|||

|

|

Cuboid | Through-beam | 15000 mm | Manual adjustment | M8 pigtail connector 4 pin | 0.3 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | IP67 | CELLULE PHOTO BARRAGE NPN |

|

|||

|

|

Cuboid | Through-beam | 10000 mm | Manual adjustment | Cable | 0.5 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | IP67 | Barrage, 10 m, DEL rouge pour filtre de polarisation, NPN, IP67, câble 0,5 m |

|

|||

|

|

Cuboid | Through-beam | 10000 mm | Manual adjustment | Cable | 2 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | IP67 | Cellule photoélectrique barrage, 10 m, DEL rouge pour filtre de polarisation, NPN, IP67, câble 2 m |

|

|||

|

|

Cuboid | Through-beam | 10000 mm | Manual adjustment | Cable | 5 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | IP67 | Barrage, 10 m, DEL rouge pour filtre de polarisation, NPN, IP67, câble 5 m |

|

|||

|

|

Cuboid | Through-beam | 10000 mm | Manual adjustment | M12 pigtail connector | 0.3 m | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | IP67 | Photoelectric sensor, rectangular housing, red LED, through-beam, 10 m, NPN, Light-ON/Dark-ON, M12 pigtail connector, 0.3 m |

|

|||

|

|

Cuboid | Through-beam | 30000 mm | Manual adjustment | Cable | 2 m | NPN | Dark-ON, Light-ON | 2 ms | PBT | Other | Infrared light | 12-24 V | IP67 | Cellule photoélectrique barrage, 30 m, CC NPN, câble 2m |

|

|||

|

|

Cuboid | Through-beam | 15000 mm | Manual adjustment | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | IP67 | Cellule photoélectrique barrage 15 m CC NPN connecteur M08 |

|

||||

|

|

Cuboid | Through-beam | 10000 mm | Manual adjustment | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | IP67 | Cellule photoélectrique barrage, 10 m, CC NPN connecteur M08 |

|

||||

|

|

Cuboid | Through-beam | 30000 mm | Manual adjustment | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 2 ms | PBT | Other | Infrared light | 12-24 V | IP67 | Cellule photoélectrique barrage, 30 m, CC NPN connecteur M08 |

|

||||

|

|

Cuboid | Through-beam | 15000 mm | Manual adjustment | Cable | 0.5 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | IP67 | Barrage, 15 m, DEL infrarouge, PNP, IP67, câble 0,5 m |

|

|||

|

|

Cuboid | Through-beam | 15000 mm | Manual adjustment | Cable | 2 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | IP67 | Cellule photoélectrique barrage, 15 m, Led infrarouge, PNP, IP67, câble 2 m |

|

|||

|

|

Cuboid | Through-beam | 15000 mm | Manual adjustment | Cable | 5 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | IP67 | Barrage, 15 m, DEL infrarouge, PNP, IP67, câble 5 m |

|

|||

|

|

Cuboid | Through-beam | 15000 mm | IO-Link, Manual adjustment | Cable | 2 m | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 10-30 V | IP67 | Cellule photoélectrique, barrage, 15m, DC, PNP, câble 2m, IO-link, COM 3 |

|

|||

|

|

Cuboid | Through-beam | 15000 mm | IO-Link, Manual adjustment | Cable | 5 m | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 10-30 V | IP67 | Cellule photoélectrique, barrage, 15m, DC, PNP, câble 5m, IO-link, COM 3 |

|

|||

|

|

Cuboid | Through-beam | 15000 mm | Manual adjustment | M12 pigtail connector | 0.3 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | IP67 | CELL PHOTO BARR15M CC PNP CONM12 |

|

|||

|

|

Cuboid | Through-beam | 15000 mm | Manual adjustment | M12 pigtail Smartclick connector | 0.3 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | IP67 | Photoelectric sensor, rectangular housing, infrared LED, through-beam, 15 m, PNP, Light-ON/Dark-ON, M12 pigtail Smartclick connector with protective tube, 0.3 m |

|

|||

|

|

Cuboid | Through-beam | 15000 mm | IO-Link, Manual adjustment | M12 pigtail Smartclick connector | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 10-30 V | IP67 | Cellule photoélectrique, barrage, 15m, DC, PNP, précâblée connecteur M12, IO-link, COM 3 |

|

|||

|

|

Cuboid | Through-beam | 15000 mm | Manual adjustment | M8 pigtail connector 4 pin | 0.3 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | IP67 | Capteur photoélectrique, boîtier rectangulaire, LED infrarouge, barrage, 15 m, PNP, Light-ON/Dark-ON, connecteur M8 à 4 broches, 0,3 m |

|

|||

|

|

Cuboid | Through-beam | 10000 mm | Manual adjustment | Cable | 0.5 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | IP67 | CELL PHOTO BARR15M CC PNP CAB0,5M |

|

|||

|

|

Cuboid | Through-beam | 10000 mm | Manual adjustment | Cable | 2 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | IP67 | Cellule photoélectrique barrage, 10 m, Led rouge pour filtre de polarisation, PNP, IP67, câble 2 m |

|

|||

|

|

Cuboid | Through-beam | 10000 mm | Manual adjustment | M12 pigtail connector | 0.3 m | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | IP67 | CELL PHOTO BARR |

|

|||

|

|

Cuboid | Through-beam | 30000 mm | Manual adjustment | Cable | 2 m | PNP | Dark-ON, Light-ON | 2 ms | PBT | Other | Infrared light | 12-24 V | IP67 | Cellule photoélectrique barrage, 30 m, Led infrarouge, PNP, IP67, câble 2 m |

|

|||

|

|

Cuboid | Through-beam | 15000 mm | Manual adjustment | Connector M8 - 4 pin | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 12-24 V | IP67 | Cellule photoélectrique barrage, 15 m, Led infrarouge, PNP, IP67, avec connecteur |

|

||||

|

|

Cuboid | Through-beam | 15000 mm | IO-Link, Manual adjustment | Connector M8 - 4 pin | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Infrared light | 10-30 V | IP67 | Cellule photoélectrique, barrage, 15m, DC, PNP, connecteur M8, IO-link, COM 3 |

|

||||

|

|

Cuboid | Through-beam | 10000 mm | Manual adjustment | Connector M8 - 4 pin | PNP | Dark-ON, Light-ON | 1 ms | PBT | Other | Polarized red light | 12-24 V | IP67 | Cellule photoélectrique barrage, 10 m, Led rouge pour filtre de polarisation, PNP, IP67, connecteur M8 4 broches |

|

||||

|

|

Cuboid | Through-beam | 30000 mm | Manual adjustment | Connector M8 - 4 pin | PNP | Dark-ON, Light-ON | 2 ms | PBT | Other | Infrared light | 12-24 V | IP67 | Cellule photoélectrique barrage, 30 m, Led infrarouge, PNP, IP67, connecteur M8 4 broches |

|

Accessoires

Reflectors for retro-reflective photoelectric sensors

|

Recommended for fine beam coaxial models (E3NC-LH03, |

|||||||

|

Round shape with centered mounting hole for simple screw mounting |

|||||||

Note: the ambient operating temperature is -25°C to 55°C unless otherwise specified

|

Recommended for fine beam and |

|||||||

Note: Note: the ambient operating temperature is -25°C to 55°C unless otherwise specified

En quoi pouvons-nous vous aider ?

Pour toute question ou demande de devis, veuillez nous contacter ou envoyer une demande.

Contactez-moi E3Z

Merci de votre demande. Nous reviendrons vers vous dès que possible.

Nous rencontrons des problèmes techniques. Votre demande ne peut être traitée. Veuillez nous excuser et ré-essayer plus tard. Détails :

DownloadDevis pour E3Z

Vous pouvez utiliser ce formulaire pour demander un devis sur le produit de votre choix. Merci de compléter tous les champs *. Les informations sont traitées de manière confidentielle.

Merci de votre demande. Nous vous enverrons l'information demandée au plus tôt.

Nous rencontrons des problèmes techniques. Votre demande ne peut être traitée. Veuillez nous excuser et ré-essayer plus tard. Détails :

DownloadFonctions

One mounting

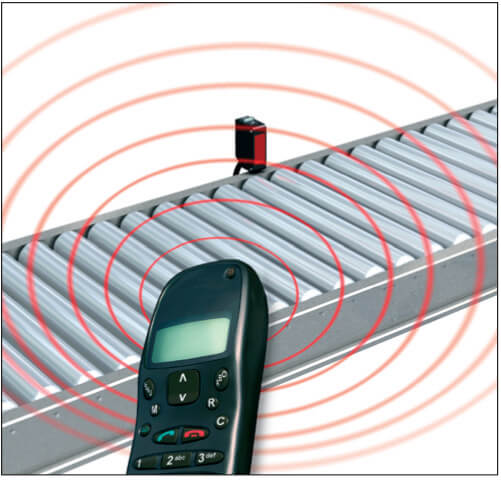

Ambient light immunity

Il n'est jamais possible de contrôler totalement les conditions environnementales des installations importantes telles que la manipulation de matériaux ou la logistique. La fiabilité de détection reste cruciale pour assurer un fonctionnement sans arrêt de ces systèmes. La lumière ambiante peut occasionner des déclenchements intempestifs chez les capteurs conventionnels. La synchronisation par impulsion et les filtres à longueur d'onde assurent une détection sans erreur due à la lumière ambiante.

EMC noise immunity

Haute immunité aux interférences électromagnétiques

IP69k

Le test IP69k DIN 40 050 partie 9 est conçu pour simuler les nettoyages à haute pression ou à vapeur. 14 à 16 l d'eau par mn à 80 ºC sont pulvérisés sur le capteur à partir de différent angles à 8000-10000 kPa. Le capteur ne doit pas subir de dommage dans sa conception ni dans ses fonctionnalités.

Vidéos

-

Predictive Maintenance by using OMRON's IO-Link Photoelectric Sensor

OMRON's IO-Link photoelectric sensor helps you understand unstable situations in the incident level of the photoelectric sensor in advance to reduce sudden stops. In the past, dust or dirt accumulated on the detection surface of the photoelectric sensor, leading to a decline in the light incident level that causes the sensor to make false detection and the device to stop. The IO-LInk demo unit simulates the situation where the incident level decreases. With an IO-LInk Photoelectric Sensor, a light incident level monitor prevents false detection. Learn more about E3Z Photoelectric Sensor

01:48

Predictive Maintenance by using OMRON's IO-Link Photoelectric Sensor

OMRON's IO-Link photoelectric sensor helps you understand unstable situations in the incident level of the photoelectric sensor in advance to reduce sudden stops. In the past, dust or dirt accumulated on the detection surface of the photoelectric sensor, leading to a decline in the light incident level that causes the sensor to make false detection and the device to stop. The IO-LInk demo unit simulates the situation where the incident level decreases. With an IO-LInk Photoelectric Sensor, a light incident level monitor prevents false detection. Learn more about E3Z Photoelectric Sensor

-

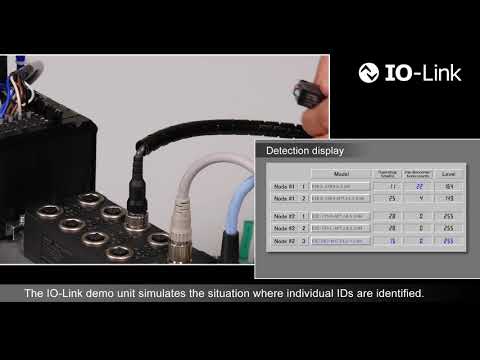

Prevent Installation Mistakes with the Individual Product Indentification by IO-Link | OMRON

OMRON's IO-Link compliant devices enable you to check identifications in batches to improve system commissioning and changeover efficiency. Previously during system startup or changeover, operators had to perform the I/O check for each of the thousands of sensors installed on the line, which took a lot of time. The IO-LInk demo unit simulates the situation where an individual's IDs are identified. You can check that the correct sensor has been connected. With the Individual Product Identification of the IO-Link you are notified of sensor models, operating time and the number of line disconnections in real-time to be able to prevent installation mistakes Learn more about E3Z Photoelectric Sensor

01:57

Prevent Installation Mistakes with the Individual Product Indentification by IO-Link | OMRON

OMRON's IO-Link compliant devices enable you to check identifications in batches to improve system commissioning and changeover efficiency. Previously during system startup or changeover, operators had to perform the I/O check for each of the thousands of sensors installed on the line, which took a lot of time. The IO-LInk demo unit simulates the situation where an individual's IDs are identified. You can check that the correct sensor has been connected. With the Individual Product Identification of the IO-Link you are notified of sensor models, operating time and the number of line disconnections in real-time to be able to prevent installation mistakes Learn more about E3Z Photoelectric Sensor

-

Detecting Connection Faults by IO-Link | OMRON

OMRON's IO-Link compliant devices detect wiring cable disconnections and error to improve equipment operation range through quick maintenance. Previously an error message was displayed on the abnormality display screen, but no external error was detected and the cause of the stop was not understood. The IO-LInk demo unit simulates sensor cable line disconnections in real-time. In this way, with an IO-Link Photoelectric Sensor /Proximity Sensor faulty parts and such phenomena in the Seosr are detected in real-time to improve equipment operation rates. Learn more about E3Z Photoelectric Sensor

01:47

Detecting Connection Faults by IO-Link | OMRON

OMRON's IO-Link compliant devices detect wiring cable disconnections and error to improve equipment operation range through quick maintenance. Previously an error message was displayed on the abnormality display screen, but no external error was detected and the cause of the stop was not understood. The IO-LInk demo unit simulates sensor cable line disconnections in real-time. In this way, with an IO-Link Photoelectric Sensor /Proximity Sensor faulty parts and such phenomena in the Seosr are detected in real-time to improve equipment operation rates. Learn more about E3Z Photoelectric Sensor

-

OMRON's IO-Link Technology

At the extreme end of production sites, there are many IO sensors that are not connected to the network. Have you experienced any trouble for not monitoring the operating status of those sensors? You couldn't recognize a defect until a machine stopped because of disconnection, short-circuit or lower detection performance you couldn't grasp the sign of the trouble. Due to this you had to take a lot of time and effort to fix this issue. OMRON's IO-Link compliant components prevent a loss caused by machine shutdown and improve the operating rate. With OMRON's IO-Link solution you are able to see the amount of light received by the sensor and a change in status in the machine when it detects a defect. You can also detect disconnection Learn more about E3Z Photoelectric Sensor

01:40

OMRON's IO-Link Technology

At the extreme end of production sites, there are many IO sensors that are not connected to the network. Have you experienced any trouble for not monitoring the operating status of those sensors? You couldn't recognize a defect until a machine stopped because of disconnection, short-circuit or lower detection performance you couldn't grasp the sign of the trouble. Due to this you had to take a lot of time and effort to fix this issue. OMRON's IO-Link compliant components prevent a loss caused by machine shutdown and improve the operating rate. With OMRON's IO-Link solution you are able to see the amount of light received by the sensor and a change in status in the machine when it detects a defect. You can also detect disconnection Learn more about E3Z Photoelectric SensorProduits liés

Téléchargements