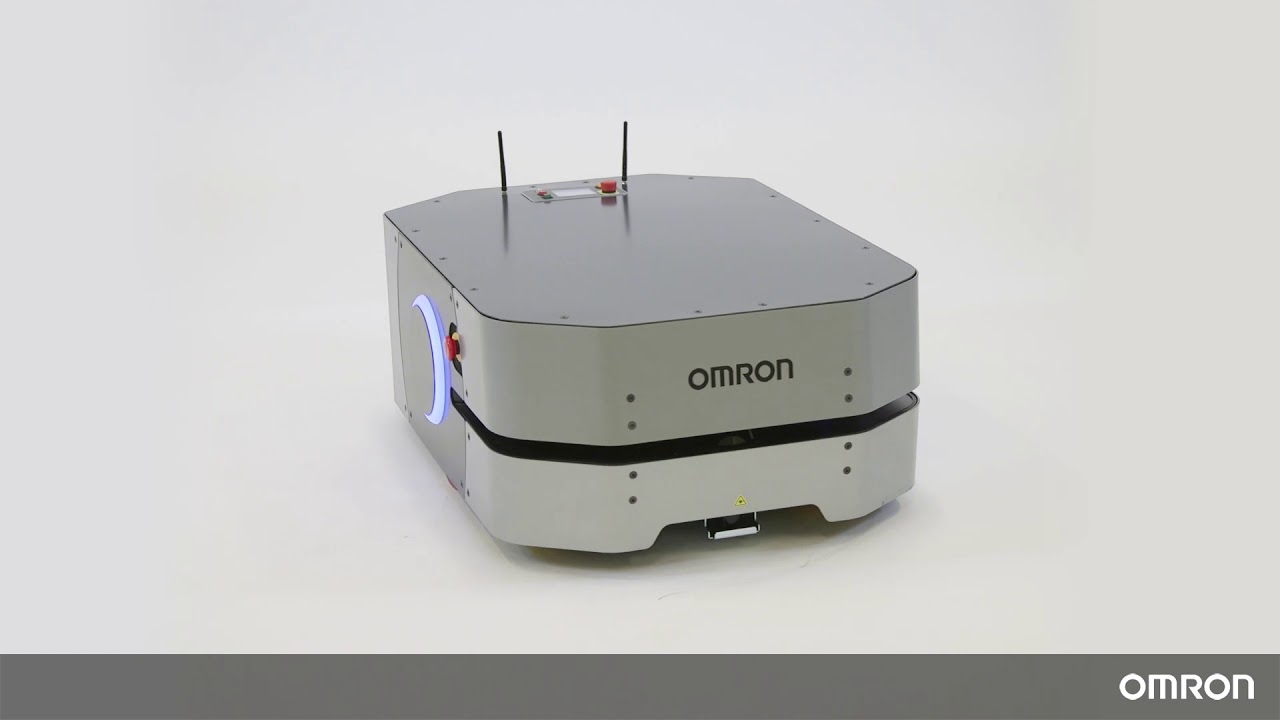

LD-series

Robots mobiles complètement autonomes

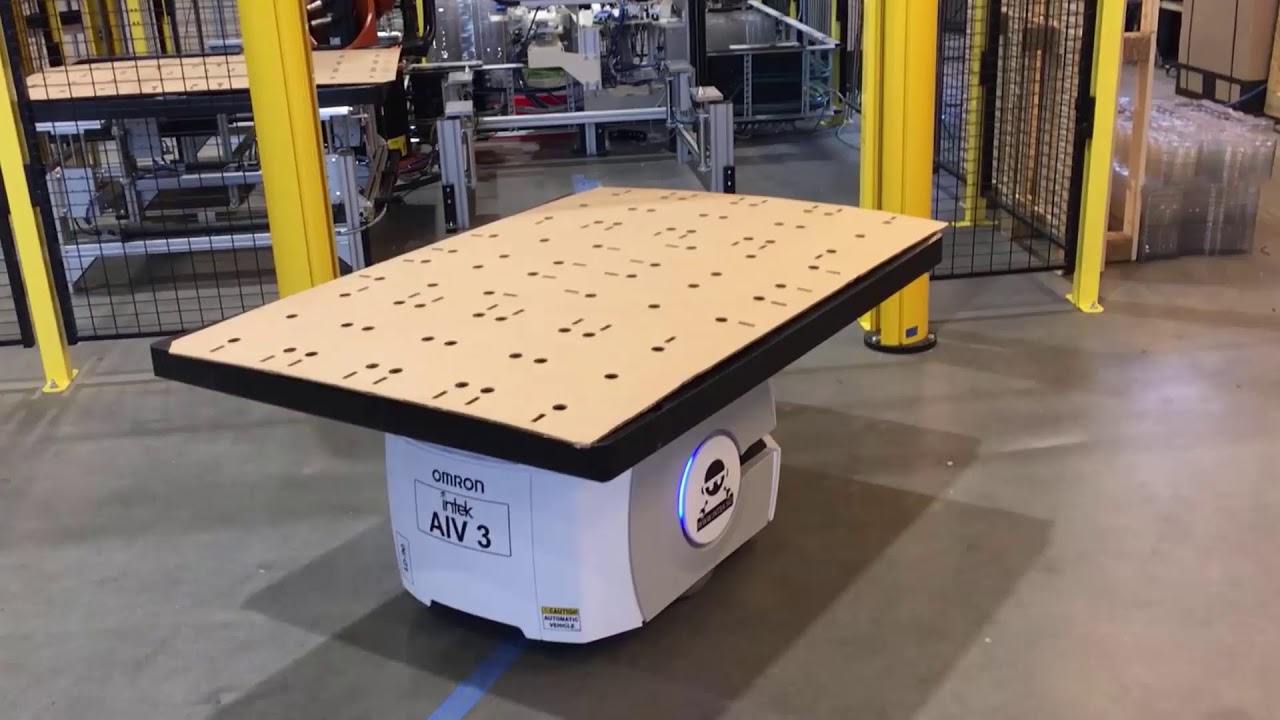

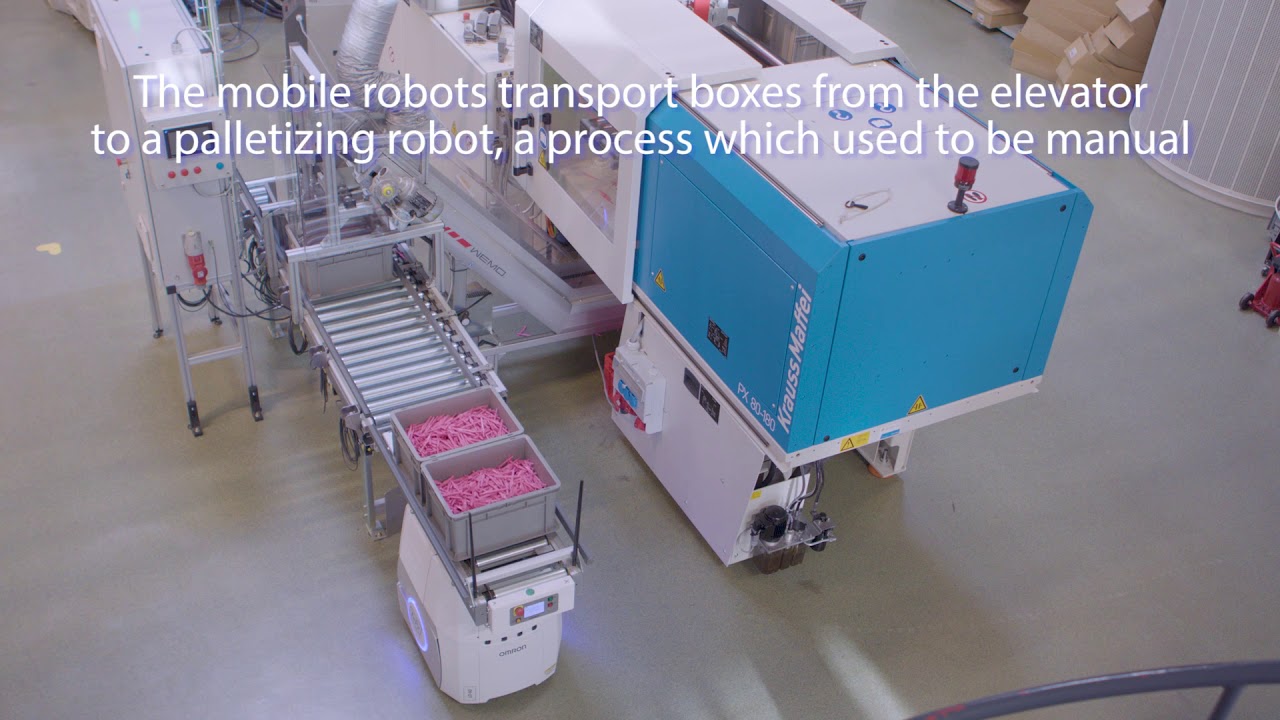

Les robots mobiles OMRON sont des robots mobiles autonomes (AMR) qui permettent d'augmenter considérablement la productivité dans les opérations de fabrication et de logistique. Nos robots mobiles augmentent le débit, éliminent les erreurs et améliorent la traçabilité des matériaux, offrant ainsi la possibilité aux employés de se concentrer sur des tâches qui requièrent des compétences humaines complexes. Qui plus est, à la différence des VGA classiques, nos robots mobiles circulent en utilisant les caractéristiques naturelles du site et ne nécessitent aucune modification coûteuse des installations.

-

Omron mobile robots

Omron's Autonomous Mobile Robots (AMRs): no facility modifications, no laser beacons, no floor magnets, no tapes and setup the robot within an hour.

01:49

Omron mobile robots

Omron's Autonomous Mobile Robots (AMRs): no facility modifications, no laser beacons, no floor magnets, no tapes and setup the robot within an hour.Robot mobile autonome (RMA) à navigation automatique

LD-series Mobile Robot Datasheet

Fonctions

Installation facile

-

1Des décisions faciles et des coûts réduitsOMRON propose un modèle d'abonnement au coût initial plus faible, ainsi que des mises à niveau et améliorations continues pour assurer le bon fonctionnement des fonctions. Le client peut prendre des décisions plus facilement.

-

2Sélectionnez des applications et fonctionnalités supplémentairesOMRON compte plusieurs succès impliquant des fonctionnalités supplémentaires. Les commerciaux d'OMRON peuvent conseiller les clients sur les meilleures solutions.

-

3Cartographie et définition des objectifsAprès une exploration rapide de votre installation, le robot établira une carte personnalisée de votre site et définira des objectifs pour les prélèvements et les livraisons.

-

4Utilisation facileLe fonctionnement intuitif par tablette et l'intégration simple entre le gestionnaire de flotte OMRON et vos MES et WMS vous permettent d'exploiter vos robots immédiatement.

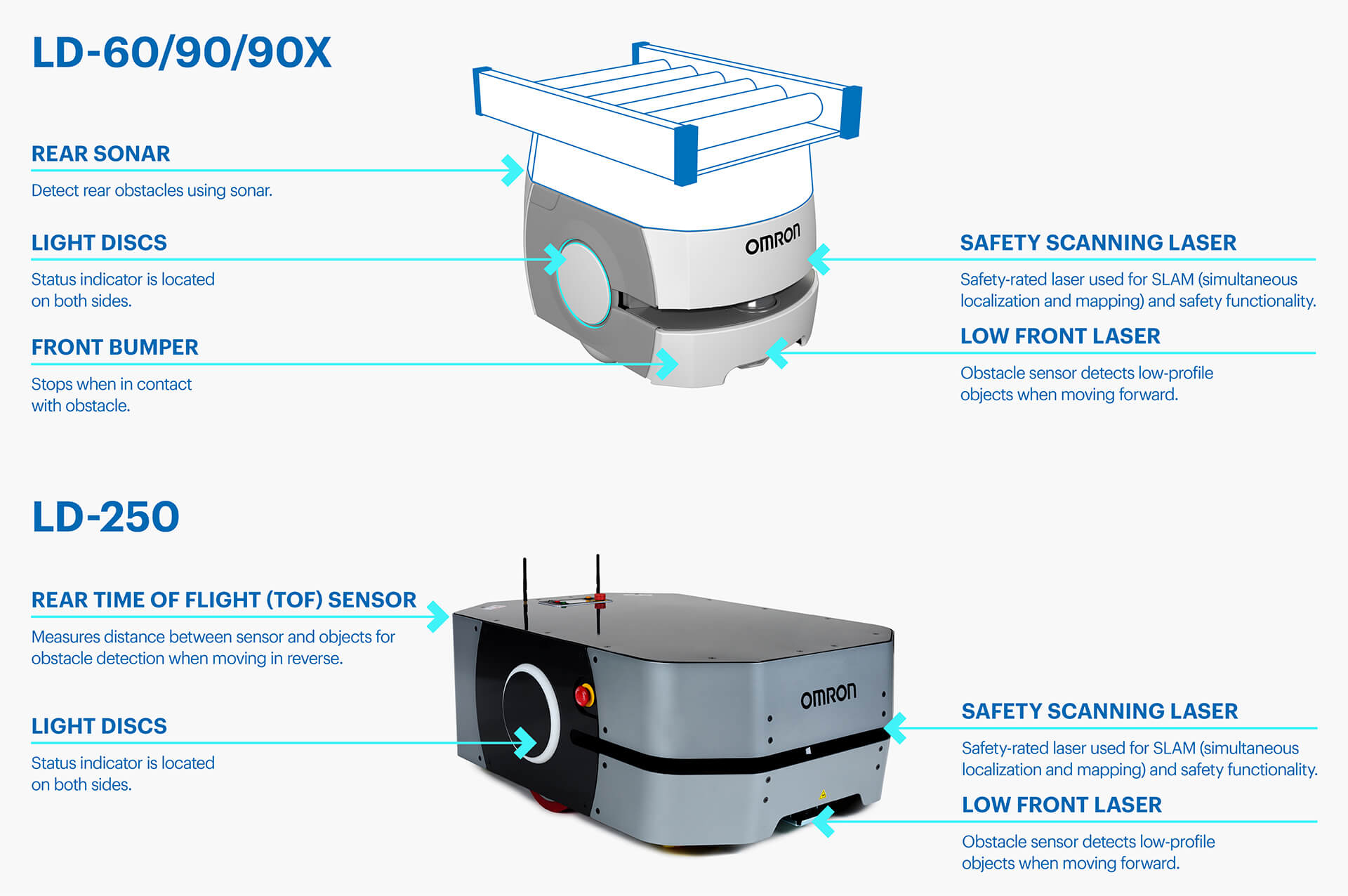

Sécurité

Le niveau de sécurité de nos robots mobiles est certifié. Ils utilisent des lasers ainsi que d'autres capteurs embarqués pour détecter les obstacles qui entravent leur chemin et, selon leur vitesse de déplacement, déclenchent un arrêt d'urgence pour éviter toute collision avec les objets se trouvant sur leur chemin.

- Laser LIDAR

- Laser inférieur

- Laser latéral

- Pare-chocs avant

- Sonar

Fonctions de sécurité

-

1Évite les obstacles statiques et mobiles

-

2Ajout facile d'arrêts d'urgence supplémentaires

-

3Conforme aux normes de sécurité ISO EN1525, JIS D6802 et ANSI B56.5

Technologie

Technologie et logiciel intégrés aux AMR

Les robots mobiles autonomes (AMR) d'OMRON sont équipés de la technologie AMR dédiée pour la navigation et l'alignement des positions. Cette technologie permet aux AMR de se déplacer efficacement et en toute sécurité dans les espaces de travail désignés, même dans des environnements complexes. Les AMR sont également commandés par un logiciel, ce qui les rend faciles à utiliser et à programmer.

- La technologie AMR dédiée utilisée par les AMR d'OMRON comprend une variété de capteurs, tels que des scanners laser, qui permettent aux robots de cartographier avec précision leur environnement et de naviguer en toute sécurité.

- Le logiciel utilisé pour faire fonctionner les AMR d'OMRON est convivial et intuitif, ce qui facilite la programmation des robots pour effectuer des tâches spécifiques.

Navigation fiable

-

Omron's LD mobile robots automate material transport and increase efficiency - full version

Handling high-mix and low volume production, whilst compensating labour shortage are challenges for Omron manufacturing in Japan. See how LD mobile robots are used to automate material transport and increase efficiency, to accelerate human-machine collaboration.

03:47

Mobile robots smarten up Toyota’s new parts centre

Modèles

Plates-formes LD-60, LD-90 et LD-90x

Notre plate-forme mobile OEM permet aux développeurs de créer des applications et charges utiles personnalisées. Elle comprend notre logiciel d'autonavigation, idéal pour une utilisation dans des environnements encombrés, des couloirs étroits et pour les applications où les véhicules automatisés présentent un avantage. Nos partenaires OEM et développeurs de charge utile ont accès à un système d'entraînement fiable, à un bloc d'alimentation embarqué, à un système de charge automatique et à des E/S pour intégrer du matériel de charge utile sur une plate-forme mobile.

Notre plate-forme mobile OEM est disponible en trois configurations, toujours avec une durée de fonctionnement de 19 heures par jour :

- LD60, capable de transporter jusqu'à 60 kg (vitesse maximale de 1,8 m/s)

- LD90, capable de transporter jusqu'à 90 kg (vitesse maximale de 1,35 m/s)

- LD-90x, à utiliser dans une configuration de transporteur de chariot pour augmenter la charge utile maximale jusqu'à 170 kg (vitesse maximale de 0,9 m/s)

Plate-forme LD-250

- LD-250 pouvant transporter jusqu'à 250 kg (vitesse maximale de 1,2 m/s)

LD-250 Dépliant

Plates-formes ESD LD-60/90/90x/250

Les robots ESD sont conçus pour les environnements de production complexes et vous permettent d'étendre vos applications de manutention automatisée tout en restant protégé. Ils sont également conçus pour protéger vos produits sensibles aux décharges électrostatiques (ESDS).

Les habillages ESD créent une protection autour du robot qui protège non seulement votre investissement, mais dissipe également l'énergie statique dans le sol en toute sécurité. Avec les robots mobiles ESD de la série LD, nous fournissons une solution sécurisée permettant de manipuler des composants sensibles à l'électricité statique.

- Protection commune pour vos produits « sensibles aux décharges électrostatiques » (ESDS) et la série LD.

- Conforme à la norme IEC 61340-5-1 comme surfaces statiques contrôlées avec Rg < 1 x 10^9.

- Protection des intensités de champ supérieures à environ 40 kV/cm d'air.

- Revêtements conçus pour résister à l'accumulation d'électricité statique.

LD-250 ESD Dépliant

Caractéristiques et références

| Produit | Mobile robot type | Maximum load | Maximum speed | Kit type | ESD protection | Battery included | Description | |

|---|---|---|---|---|---|---|---|---|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot | No | No | Robot mobile, LD-60, sans batterie |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot + docking kit | No | No | Robot mobile Bundle, LD-60, avec chargeur, sans batterie |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot + starter kit | No | No | Robot mobile Starter Kit, LD-60, avec chargeur, sans batterie, Joystick, plateau supérieur |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot | Yes | No | Robot mobile, LD-60, ESD, sans batterie |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot + docking kit | Yes | No | Robot mobile Bundle, LD-60, ESD, avec chargeur, sans batterie |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot + starter kit | Yes | No | Robot mobile Starter Kit, LD-60, ESD, sans batterie, avec chargeur, Joystick, plateau supérieur |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot | No | No | Robot mobile, LD-90, sans batterie |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot + docking kit | No | No | Robot mobile Bundle, LD-90, avec chargeur, sans batterie |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot + starter kit | No | No | Robot mobile Starter Kit, LD-90, avec chargeur, sans batterie, Joystick, plateau supérieur |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot | Yes | No | Robot mobile, LD-90, ESD, sans batterie |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot + docking kit | Yes | No | Robot mobile Bundle, LD-90, ESD, avec chargeur, sans batterie |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot + starter kit | Yes | No | Robot mobile Starter Kit, LD-90, ESD, sans batterie, avec chargeur, Joystick, plateau supérieur |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot | No | No | Robot mobile, LD-90x, sans batterie |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot + docking kit | No | No | Robot mobile Bundle, LD-90x, avec chargeur, sans batterie |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot + starter kit | No | No | Robot mobile Starter Kit, LD-90x, avec chargeur, sans batterie, Joystick, plateau supérieur |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot | Yes | No | Robot mobile, LD-90x, ESD, sans batterie |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot + docking kit | Yes | No | Robot mobile Bundle, LD-90x, ESD, avec chargeur, sans batterie |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot + starter kit | Yes | No | Robot mobile Starter Kit, LD-90x, ESD,sans batterie, avec chargeur, Joystick, plateau supérieur |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot | No | No | Robot mobile, LD-250, sans batterie |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot + docking kit | No | No | Mobile Robot Docking Station Kit, LD-250, chargeur, sans batterie |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot + starter kit | No | No | Mobile Robot Starter Kit, LD-250, avec chargeur, sans batterie, Joystick, plateau supérieur |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot | Yes | No | Robot mobile, LD-250, esd, sans batterie |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot + docking kit | Yes | No | Kit de station d'accueil pour robot mobile, LD-250, esd, chargeur, sans batterie |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot + starter kit | Yes | No | Kit de démarrage pour robot mobile, LD-250, esd, avec chargeur, sans batterie, joystick, plaque supérieure |

|

Accessoires

Filtrer par

Chariot à étagères NORD

Nord Modules

Evy-Box

Meanwhile

Module supérieur AMR LCP pour le LD-250 d'OMRON

Interroll

Module supérieur AMR LCP pour le LD-60/90 d'OMRON

Interroll

NORD QM200-OMRON

Nord Modules

NORD QM35 + 65 - OMRON

Nord Modules

Porte On-The-Fly NORD P&D

Nord Modules

Porte de base NORD

Nord Modules

Suivant

Nous sommes là pour vous aider

Une question ? Nos spécialistes sont là pour vous guider à chaque étape.

Contactez-moi LD-series

Merci de votre demande. Nous reviendrons vers vous dès que possible.

Nous rencontrons des problèmes techniques. Votre demande ne peut être traitée. Veuillez nous excuser et ré-essayer plus tard. Détails :

DownloadDevis pour LD-series

Vous pouvez utiliser ce formulaire pour demander un devis sur le produit de votre choix. Merci de compléter tous les champs *. Les informations sont traitées de manière confidentielle.

Merci de votre demande. Nous vous enverrons l'information demandée au plus tôt.

Nous rencontrons des problèmes techniques. Votre demande ne peut être traitée. Veuillez nous excuser et ré-essayer plus tard. Détails :

DownloadSolutions

Solution de manipulateur mobile OMRON

Cas client

-

Mobile robots streamline internal logistics at HIPRA

Autonomous mobile robots increase the flexibility, efficiency, and productivity of material transport. HIPRA, a pioneering biotechnological company in the pharmaceutical industry, has transformed its internal logistics processes by installing a fleet of mobile robots supplied by OMRON. Read more:

03:30

Mobile robots streamline internal logistics at HIPRA

Autonomous mobile robots increase the flexibility, efficiency, and productivity of material transport. HIPRA, a pioneering biotechnological company in the pharmaceutical industry, has transformed its internal logistics processes by installing a fleet of mobile robots supplied by OMRON. Read more:

-

Operators and robots work in harmony: Grupo Antolin automates handling of car interior components

Major trends in the automotive industry – including an increasing emphasis on issues such as electrification, digitalization, and sustainability – are also driving changes in vehicle interiors. One of the largest international players in this sector is Grupo Antolin. As a key player at global automotive supply chain and high value manufacturing leader, the strategy of the company, Adv. Manufacturing 4.0, looks into integration of digital technology in the operations. One of the focus areas is the reduction and optimization of movements in internal logistic. Introducing autonomous mobile robots (AMRs) and collaborative robots (cobots), manufactured and supplied by OMRON, helps achieve a modernized and more sustainable factory where people and machines are working in harmony. For more information, visit:

03:11

Operators and robots work in harmony: Grupo Antolin automates handling of car interior components

Major trends in the automotive industry – including an increasing emphasis on issues such as electrification, digitalization, and sustainability – are also driving changes in vehicle interiors. One of the largest international players in this sector is Grupo Antolin. As a key player at global automotive supply chain and high value manufacturing leader, the strategy of the company, Adv. Manufacturing 4.0, looks into integration of digital technology in the operations. One of the focus areas is the reduction and optimization of movements in internal logistic. Introducing autonomous mobile robots (AMRs) and collaborative robots (cobots), manufactured and supplied by OMRON, helps achieve a modernized and more sustainable factory where people and machines are working in harmony. For more information, visit:

-

Mobile order preparation and operator support solution from Savoye with OMRON mobile robots

The Mobile Robot solution from Savoye is a flexible and economical alternative to manual processes. Mobile robots move autonomously, carrying packages and items to the various areas of the warehouse, allowing operators to be freed from: - Routes between launching area, picking areas and packaging areas - Fatigue generated by cart handling activities The operators remain in their picking area, thus devoting their time to value-added operations. The Savoye Mobile Robot solution can be used in stand-alone mode, independently interfaced with Savoye WMS and WCS software, or in addition to an automated system. There are many use cases, all relying on the same IT architecture: - Multi-package preparation (pick & pack), - Item picking before splitting (pick-then-pack) - Replenishment of retail picking locations For more information, please visit:

03:32

Mobile order preparation and operator support solution from Savoye with OMRON mobile robots

The Mobile Robot solution from Savoye is a flexible and economical alternative to manual processes. Mobile robots move autonomously, carrying packages and items to the various areas of the warehouse, allowing operators to be freed from: - Routes between launching area, picking areas and packaging areas - Fatigue generated by cart handling activities The operators remain in their picking area, thus devoting their time to value-added operations. The Savoye Mobile Robot solution can be used in stand-alone mode, independently interfaced with Savoye WMS and WCS software, or in addition to an automated system. There are many use cases, all relying on the same IT architecture: - Multi-package preparation (pick & pack), - Item picking before splitting (pick-then-pack) - Replenishment of retail picking locations For more information, please visit:

-

Material handling solutions with autonomous mobile robots

LCS has implemented applications with OMRON autonomous mobile robots in various markets and industries that require efficient, flexible and automated logistics. LCS Group has been operating on the Italian and European markets since 1989 as a System Integrator, offering complete, integrated and cutting-edge hardware and software solutions for internal logistics, airports and industrial automation. Music in this video Inspirational Corporate Ambient Artist: Aleksandr Shamaluev Album: Corporate Music Licensed to YouTube by HAAWK for a 3rd Party (on behalf of AShamaluevMusic); HAAWK Publishing, BMI - Broadcast Music Inc., and 3 music rights societies

02:36

Material handling solutions with autonomous mobile robots

LCS has implemented applications with OMRON autonomous mobile robots in various markets and industries that require efficient, flexible and automated logistics. LCS Group has been operating on the Italian and European markets since 1989 as a System Integrator, offering complete, integrated and cutting-edge hardware and software solutions for internal logistics, airports and industrial automation. Music in this video Inspirational Corporate Ambient Artist: Aleksandr Shamaluev Album: Corporate Music Licensed to YouTube by HAAWK for a 3rd Party (on behalf of AShamaluevMusic); HAAWK Publishing, BMI - Broadcast Music Inc., and 3 music rights societiesVidéos

-

Mobile Manipulator combines a cobot arm with an autonomous mobile robot for flexible production

OMRON's autonomous mobile manipulator solution supports flexible manufacturing and improves efficiency by integrating a self-navigating LD mobile robot with OMRON's collaborative robot arm. What will you use it for?

01:43

Mobile Manipulator combines a cobot arm with an autonomous mobile robot for flexible production

OMRON's autonomous mobile manipulator solution supports flexible manufacturing and improves efficiency by integrating a self-navigating LD mobile robot with OMRON's collaborative robot arm. What will you use it for?

-

OMRON FLOW Core 3.0 MobilePlanner

Our MobilePlanner allows you to easily and effectively utilize fleets of heterogeneous robot types alongside one another to optimize their automation solution. MobilePlanner expands our Fleet Management ecosystem as the best in the industry. #omronindustrialautomation #mobilerobots

00:53

OMRON FLOW Core 3.0 MobilePlanner

Our MobilePlanner allows you to easily and effectively utilize fleets of heterogeneous robot types alongside one another to optimize their automation solution. MobilePlanner expands our Fleet Management ecosystem as the best in the industry. #omronindustrialautomation #mobilerobots

-

OMRON FLOW Core 3.0 Selectable Autonomy

Enables users to tailor traffic flow with powerful path modes, ranging from autonomous guided vehicle (AGV)—but without the costly infrastructure—to limited detour windows, to the pure flexibility of a traditional AMR. #omronindustrialautomation #mobilerobots

01:09

OMRON FLOW Core 3.0 Selectable Autonomy

Enables users to tailor traffic flow with powerful path modes, ranging from autonomous guided vehicle (AGV)—but without the costly infrastructure—to limited detour windows, to the pure flexibility of a traditional AMR. #omronindustrialautomation #mobilerobots

-

Omron Mobile Planner Tablet Edition - Intro

Introduction of the Omron Mobile Planner - an easy to use, portable, monitoring and control user interface tool for LD Mobile Robots.

03:21

Omron Mobile Planner Tablet Edition - Intro

Introduction of the Omron Mobile Planner - an easy to use, portable, monitoring and control user interface tool for LD Mobile Robots.Téléchargements

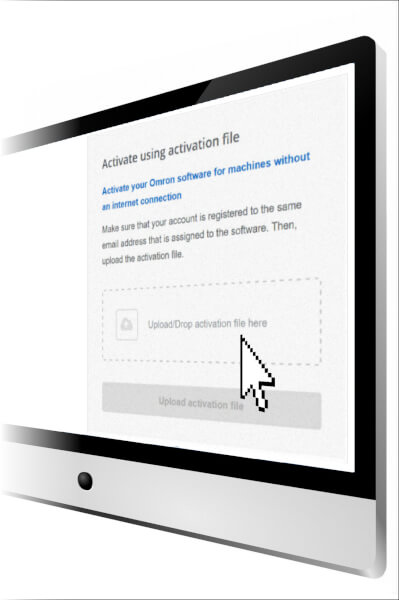

Activez votre logiciel de robot mobile

Besoin d'aide ?

Nous sommes là pour vous aider ! Contactez-nous et nos spécialistes vous aideront à trouver la meilleure solution pour votre entreprise.

Contactez-moi LD-series

Merci de votre demande. Nous reviendrons vers vous dès que possible.

Nous rencontrons des problèmes techniques. Votre demande ne peut être traitée. Veuillez nous excuser et ré-essayer plus tard. Détails :

DownloadDevis pour LD-series

Vous pouvez utiliser ce formulaire pour demander un devis sur le produit de votre choix. Merci de compléter tous les champs *. Les informations sont traitées de manière confidentielle.

Merci de votre demande. Nous vous enverrons l'information demandée au plus tôt.

Nous rencontrons des problèmes techniques. Votre demande ne peut être traitée. Veuillez nous excuser et ré-essayer plus tard. Détails :

Download

_reference_manual_en.jpg)

_leaflet_en.jpg)